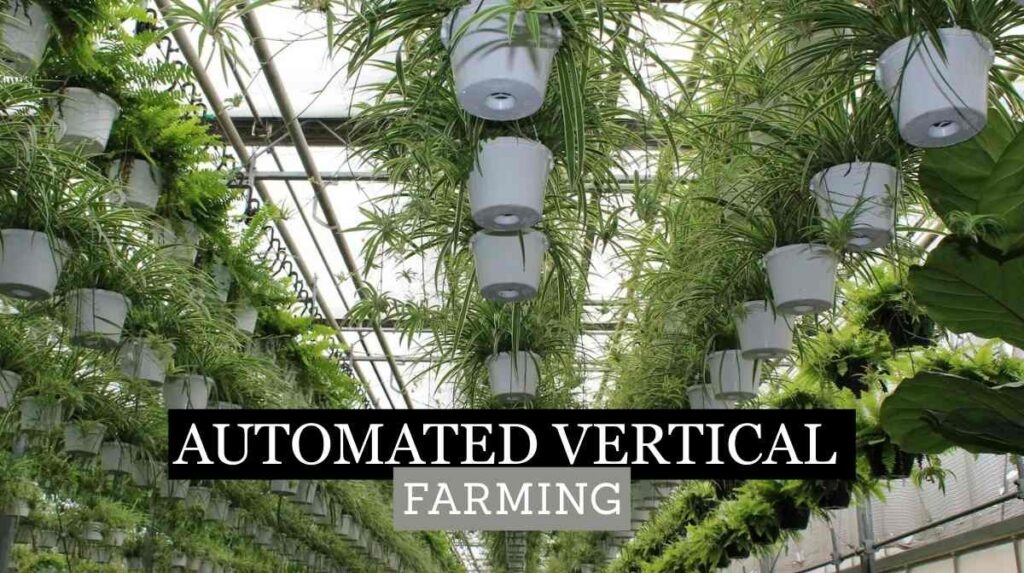

Automated vertical farming is revolutionizing agriculture by transforming how we grow food in urban environments and beyond. As global populations surge and arable land becomes increasingly scarce, this innovative approach combines cutting-edge technology with sustainable agriculture practices to maximize crop yields in minimal space. By stacking growing layers vertically and integrating smart sensors, AI-driven monitoring, and precision control systems, these farms can produce fresh produce year-round, regardless of external weather conditions.

This article explores how automated vertical farming leverages IoT sensors, robotic harvesting, and data analytics to optimize every aspect of plant growth from nutrient delivery to light exposure. We’ll examine the key technologies driving this agricultural revolution, the benefits for both commercial growers and local communities, and how climate-controlled environments are making fresh, pesticide-free produce more accessible than ever before.

What Is Automated Vertical Farming and How Does It Work?

Automated vertical farming represents a groundbreaking fusion of agricultural technology and engineering that cultivates crops in vertically stacked layers within controlled environments. Unlike traditional farming, this method employs smart irrigation systems, LED grow lights, and climate control mechanisms to create optimal growing conditions 365 days a year. The automation aspect involves sophisticated software that monitors and adjusts environmental parameters including temperature, humidity, nutrient levels, and light intensity without human intervention.

These systems utilize hydroponic farming or aeroponic techniques, eliminating the need for soil while delivering nutrients directly to plant roots through water-based solutions. Advanced sensors continuously collect data on plant health, growth rates, and environmental conditions, enabling real-time adjustments that maximize yield and minimize resource waste.

The Evolution of Vertical Agriculture Technology

Early Development and Innovation

The concept of vertical farming emerged in 1999 when Columbia University professor Dickson Despommier proposed growing food in urban skyscrapers. Initial experiments focused on basic greenhouse automation and simple stacking systems. By 2010, the first commercial vertical farms appeared in Singapore and Japan, demonstrating the viability of indoor farming systems.

Modern Technological Integration

Today’s automated vertical farming incorporates:

- Machine learning algorithms for predictive crop management

- Robotic seeding and harvesting equipment

- Precision agriculture tools for nutrient optimization

- Computer vision systems for disease detection

- Automated packaging and distribution systems

Key Benefits of Smart Farming Systems

1.Resource Efficiency and Sustainability

Automated vertical farming achieves remarkable water conservation by using 95% less water than conventional farming through recirculating systems. These facilities require minimal land area, producing equivalent yields to traditional farms that are 100 times larger. The controlled environment eliminates pesticide use entirely, resulting in cleaner, healthier produce while protecting beneficial insects and ecosystems.

2.Year-Round Production Capabilities

Climate-controlled growing environments enable consistent harvests regardless of seasonal changes or extreme weather events. This reliability ensures:

- Stable food supply chains

- Predictable pricing for consumers

- Fresh produce availability in any geographic location

- Reduced dependency on imports

3.Enhanced Crop Quality and Yield

Through LED lighting optimization, plants receive precise light spectrums tailored to their growth stages, accelerating development and improving nutritional content. Automated monitoring systems detect issues immediately, preventing crop loss and maintaining consistent quality standards that exceed traditional farming methods.

Critical Technologies Driving Agricultural Automation

Artificial Intelligence and Machine Learning

AI-powered farming systems analyze vast datasets to predict optimal harvest times, identify potential diseases, and recommend environmental adjustments. These intelligent systems learn from each growing cycle, continuously improving efficiency and yield outcomes.

Predictive Analytics Applications

Advanced algorithms process historical data alongside real-time sensor readings to forecast crop performance, enabling proactive interventions that prevent problems before they occur.

Internet of Things Integration

Smart sensors throughout the facility monitor:

- Air quality and CO2 levels

- Nutrient solution pH and electrical conductivity

- Light intensity and spectrum distribution

- Temperature gradients across growing zones

- Humidity fluctuations

This interconnected network enables remote monitoring systems that allow farmers to manage operations from anywhere globally.

Overcoming Implementation Challenges

Economic Considerations

Initial setup costs for automated vertical farming remain substantial, with investments ranging from $4 million to $40 million depending on scale. However, operational savings through reduced labor, water, and land costs typically achieve ROI within 5 to 10 years. Energy consumption, particularly for LED lighting, represents the largest ongoing expense, though improving energy-efficient growing technologies continue reducing these costs.

Technical Expertise Requirements

Operating these sophisticated systems demands specialized knowledge in:

- Agricultural robotics programming and maintenance

- Data analysis and interpretation

- Hydroponic system management

- Environmental control optimization

Real-World Success Stories

Singapore’s Sky Greens operates automated vertical farming towers producing leafy vegetables with minimal human intervention, supplying fresh produce to local supermarkets daily. In the United States, AeroFarms utilizes automated growing systems to produce over 2 million pounds of greens annually using 95% less water than field farming.

Japan’s Spread Company developed the world’s first fully autonomous vertical farm, where robots handle everything from seeding to packaging, producing 30,000 heads of lettuce daily with only minimal human oversight for system monitoring.

The Future of Food Production

As technology advances and costs decrease, automated vertical farming will become increasingly accessible to smaller operations and developing nations. Integration with renewable energy sources and improved crop monitoring technology will further enhance sustainability and profitability, positioning these systems as essential components of global food security strategies.

Conclusion

Automated vertical farming stands at the forefront of agricultural innovation, offering sustainable solutions through smart farming systems to feed our growing population while preserving precious resources. By combining AI, robotics, and precision agriculture techniques, these systems deliver consistent, pesticide-free produce with minimal environmental impact. As technology costs decline and energy-efficient growing methods improve, automated vertical farming will transform from a novel concept to an essential component of global food production. Whether you’re an investor, farmer, or conscious consumer, now is the time to explore how this revolutionary approach combining IoT sensors and sustainable practices can shape a more food-secure future for generations to come.